Sustainability is not a new concept for Uddeholm. Since the 1960s they’ve used an electric arc furnace in the smelting process at our steelworks. They have reduced their fossil CO2 emissions by 46% since 1990.

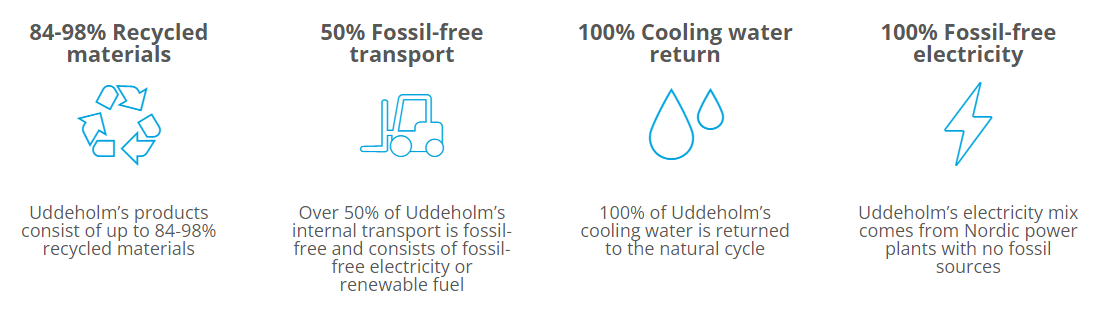

Uddeholm is already using only 100% fossil-free electricity and our products are made from 84-98% recycled material. We are convinced that new technological innovations will play an important role in many of the global environmental challenges. Uddeholm's experience, expertise and values will be the key to further development. At Uddeholm, the journey to fossil-free production and climate neutrality has started.

Uddeholm's production system and location provide them with very well suited conditions for leading this development.

By 2030 they will have fossil-free production and by 2040 the entire lifecycle of products will be climate-neutral.

Over the year they carried out activities to strengthen the work environment, which should be safe and healthy. Our business must be conducted in a way where no one gets hurt at work and where we care about each other’s safety.

In addition, Uddeholm works preventively with physical and mental health. A health policy has been developed and is continually revised to meet the standards required for a sustainable and healthy work environment.

Together, our network of experts around the world work non-stop to create solutions that are sustainable, secure and long-lasting – for our customers and for ourselves. In other words, our customers get much more from us than just steel. They also get our promise to always produce steel that is as kind on the environment as possible. Achieving this is an ongoing process and a promise that must be kept every day.