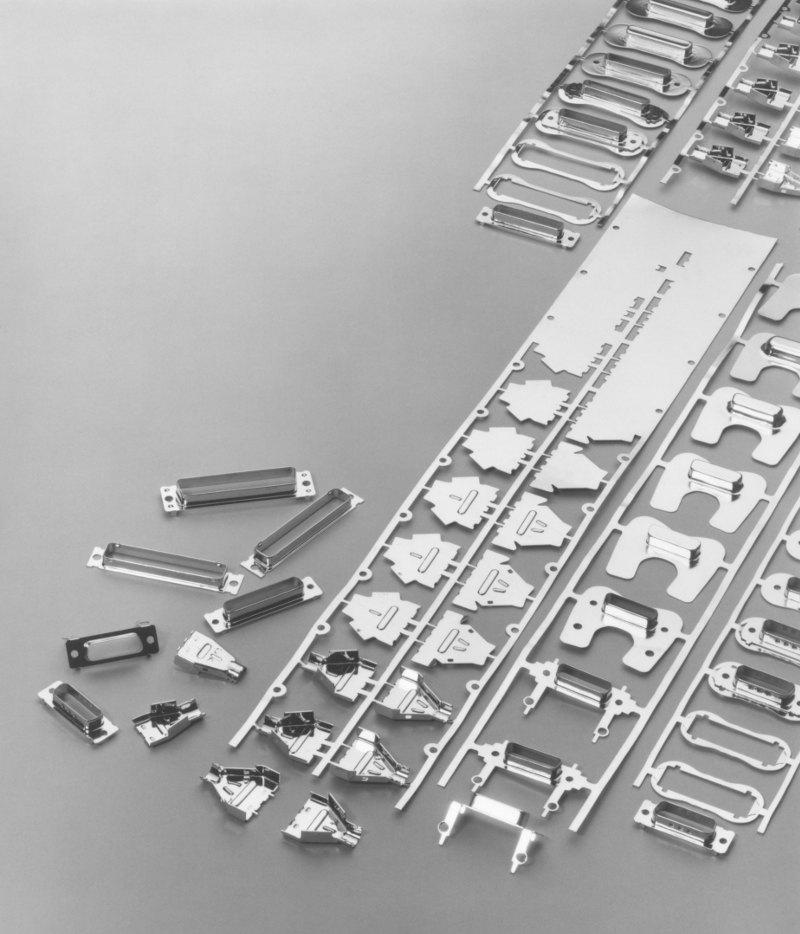

High alloyed powder metallurgical steel, equivalent to AISI M3:2 high-speed steel. It has good wear resistance in combination with a high compressive strength. It is suitable for demanding cold working applications, such as punching and cutting of carbon or cold rolled steels and cutting tools. In addition to the extraordinary dimensional stability after heat treatment, it has superior machinability and grinding to conventional high-speed steels. The pulverometallurgical casting process ensures a fine steel structure and practically free of contamination/non-metallic inclusions.