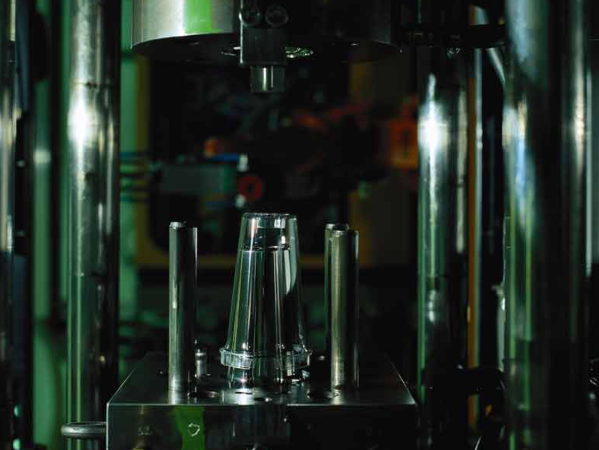

ESR (Electro Slag Remelting) steel is a specific stainless steel for small fuses and cavities of plastic injection moulds. It combines corrosion and wear resistance, presenting excellent polishing and optimum machinability and dimensional stability during heat treatment. The maintenance of the moulds is reduced drastically, ensuring the surface finish of the cavities and cores during further cycles. When the presence of corrosion is unacceptable, either due to process requirements or good hygienic practices or because they are medical or optical parts, this is the solution.